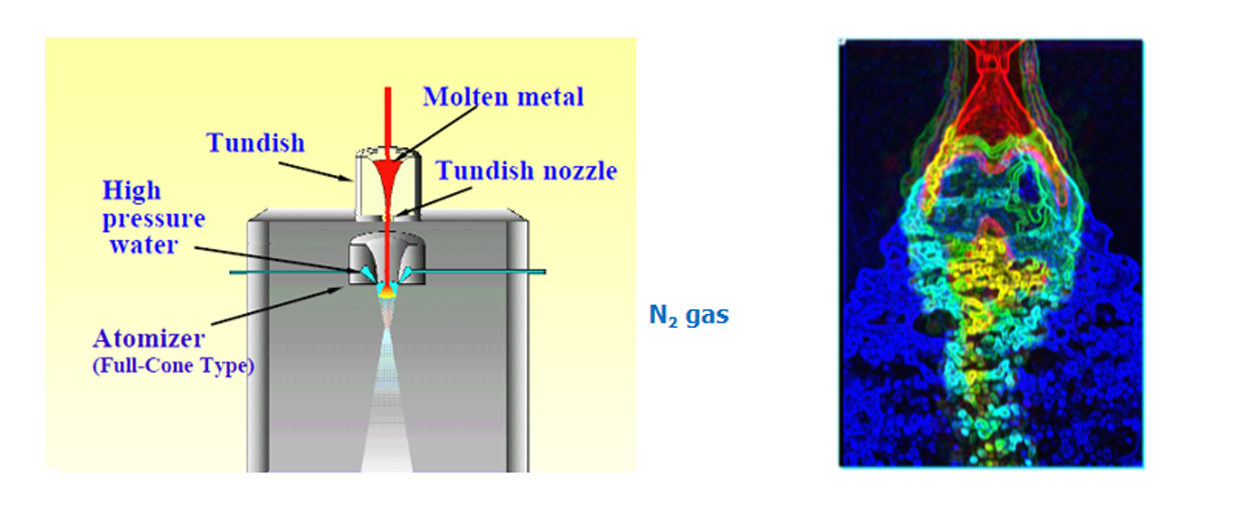

Longding’s featured water-gas combined atomization process

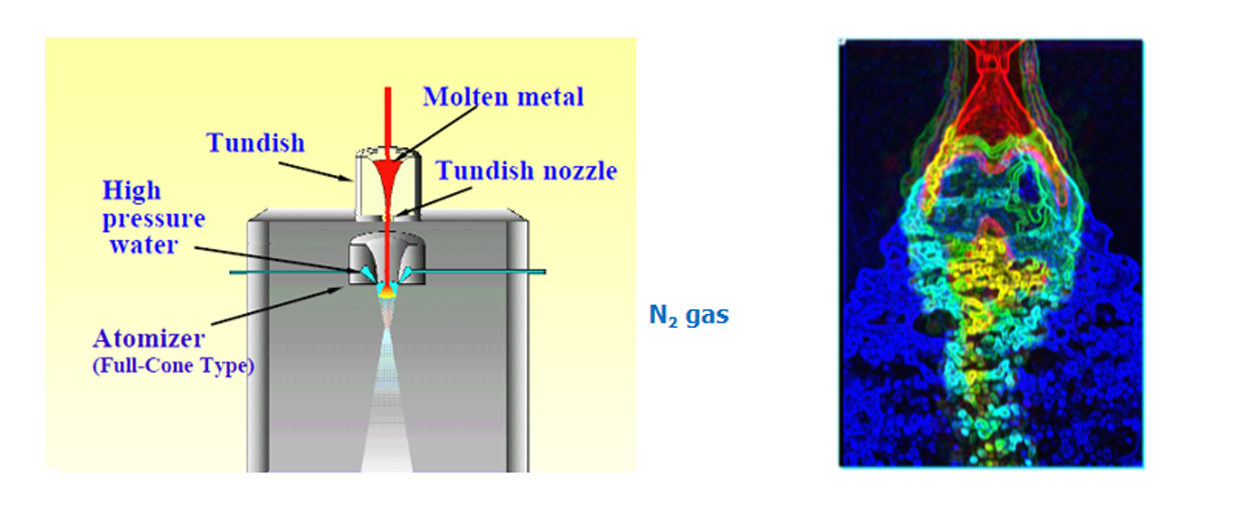

The atomizer structure is illustrated in the diagram. This design offers several advantages: Dual-stage atomization within a single atomizer: initially through gas impact followed by ultra-high-pressure water impact. The first stage pre-breaks and cools the molten steel, causing the liquid metal to form liquid waves and break into strips. The second stage fully utilizes the kinetic energy of ultra-high-pressure water to further impact and break the strips, refining them into fine spherical powder particles. Bear-spherical powders produced using this atomizer combine the excellent properties of gas atomization with a high yield of fine powders.